Hollow Screw System

Interface system

1. STANDARDIZED SUPRA CONNECTIONS

IPD Interfaces have 3 different Interface supraconnections to cover the whole range of compatibilities:

- Engaging Interface for single unit restorations. The supra connection has parallel walls increasing retention of the cement and a very low profile for excellent aesthetic results even in the cases with very low gingival height.

- Non-engaging Interface for standard multiple restorations.

- Non-engaging Interface for restorations on Multi-unit abutments. Compatible with straight and angled Multi-units.

All 3 models have their own castable abutments and scan bodies and a different section in the CAD/CAM implant library. However, they all have an internal thread on the top part of the trans-occlusal channel to allow the use of the hollow screw.

2. SCAN BODY

IPD’s Scan body is the result of an extensive research on optimal scanning methods. A very precise manufacturing process enables accurate implant position. Our Scan body can be used together with the Interface system by linking both pieces with the hollow screw; this increases the effective life of the Scan body and reduces the stock needs dramatically. IPD has released three types of Scan body:

- Engaging Scan body (Engaging Interfaces)

- Non-engaging Scan body (Non-engaging Interfaces)

- Wide non-engaging Scan body (Wide non-engaging Interfaces)

The upper Interface morphology, common to all its references, allows the users to cover any case with only 3 Scan body models, regardless of the implant connection.

3. INTERFACE HOLLOW SCREW

The Hollow screw is designed to be used with IPD Interface system. It allows the Interface to be connected mechanically to the prosthesis or any other abutment for Interface such as castable abutment or Scan body.

It is open in the longitudinal axis and enables the implant level screw to pass through in order to connect the Interface with the implant. Occlusion tests can be performed without gluing the crown to the Interface and without changing the clinical procedures.

This new concept considerably simplifies the current procedures and working methods of the dental lab, avoiding temporary cementation during the try-in stage and all the related problems this entails. The screw is made of anodized grade 5 Titanium, which is fully biocompatible. Therefore, it can be used as a permanent screw, improving the stability, reliability and durability of the structure.

Screwdriver for Hollow Screw

The attachment system is complemented with a screwdriver specially designed for the hollow screw. It has a useful and easy to use ergonomic design and it enables you to hold the hollow screw with it, to make handling easier.

The design is based on a cruciform screwdriver with a diameter reduction where the screw is inserted and acts as a guide to simplify the coupling. The connection with the handle is a standard contra-angle, compatible with the majority of tools available in the market.

4. WORK SEQUENCES

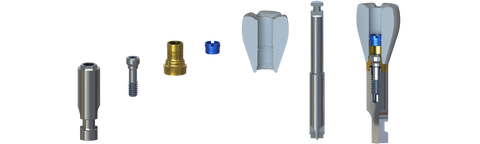

- Explosion drawing (from bottom to top): implant replica, prosthesis (or Castable abutment or scan body), Interface, Hollow screw and permanent screw.

- Hollow screw driver: Tightening of the Hollow screw.

- Permanent screw driver: The permanent screw driver is inserted through the Hollow screw so that the permanent screw can be easily tightened or loosened.

- Cementless temporary restoration: The crown is fixed mechanically to the Interface by means of a Hollow Screw. No glue or bonding material is needed during the working process or try-in.

5. ADVANTAGES

- CAD-CAM: The scanning process in the lab and the components handling are simplified. Libraries available for: Exocad, Dentalwings, 3Shape, EGS, Delcam and Imetrics.

- Uncemented temporary fixation: No cement used in any of the stages of the prosthesis manufacturing and adjusting: Metal try-in, Bisque try-in and occlusion test.

- Oxidation free: As the Interface does not require to be heated in the furnace in order to remove temporary cement, there is no oxidation on its surface. It maintains dimensional integrity and surface color, resulting in a superior appearance and a precise adjustment with the implant.

- Less time and cost: Labor time and cost reduction.

- Security fixation system: The Hollow screw is made of Grade 5 titanium and consequently it can be used as a permanent security fixation system while keeping the trans-occlusal channel free of the excess of bonding material. In no case, however, it is meant to replace the permanent cementation.

- Gingiva heights available: Gives solutions for almost all clinical cases and allows to keep the cement away from the tissues.

- Without sandblasting: The parallel and engraved walls of the supraconnection give an extra retention for the cement, being possible to avoid the sandblasting.

- TiN coated: The gold like color TiN coating offers a warmer and more natural color to the restoration, avoiding the shadows in the crown. The coating applied to the titanium is chemically stable and very uniform. Moreover, the TiN coating is completely biocompatible and reduces bacterial adhesion.

- Higher ceramic thickness: The parallel walls allow higher thickness of ceramics, reducing shadows even in compromised restorations.

- Standardized supraconnection: The standardized supraconnection reduces the stock of components required, as a result IPD Interface system is the most cost-effective interface system on the market.